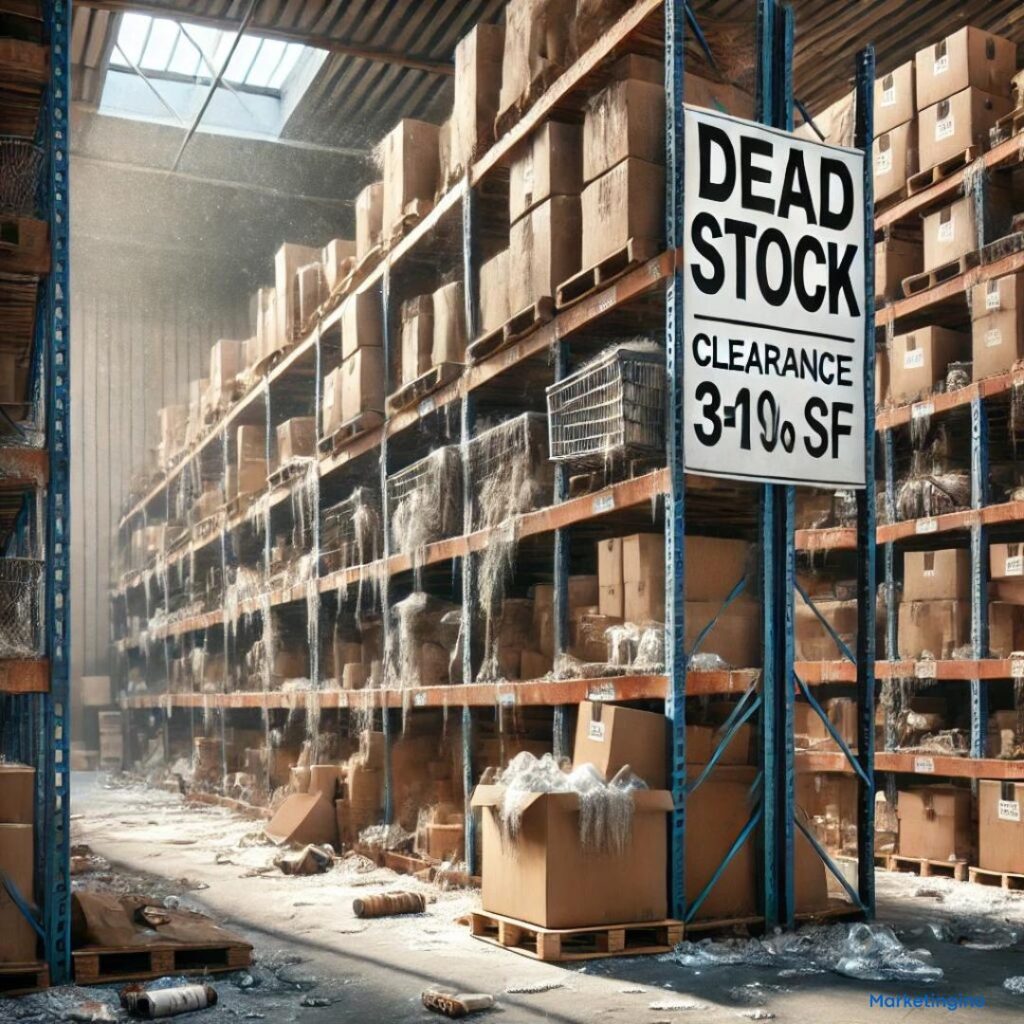

In the fast-paced world of retail and manufacturing, inventory management is a critical aspect of maintaining profitability and efficiency. One of the significant challenges businesses face in this realm is dealing with dead stock—inventory that remains unsold for an extended period and has little chance of being sold in the future. Dead stock can have a detrimental impact on a company’s bottom line, tying up capital, consuming valuable storage space, and potentially leading to obsolescence. This article explores the nature of dead stock, its causes, and strategies for effectively managing and mitigating its impact.

What is Dead Stock?

Dead stock, also known as obsolete inventory or excess inventory, refers to products that have not been sold or used for a long period and are unlikely to be sold in the future. Unlike slow-moving inventory, which may still have potential for sale, dead stock is typically considered unsellable under current market conditions. This inventory can include outdated products, seasonal items left over after their peak selling season, or goods that have fallen out of favor with consumers.

Causes of Dead Stock

Several factors can contribute to the accumulation of dead stock:

- Overestimating Demand: One of the primary causes of dead stock is inaccurate demand forecasting. Overestimating the demand for certain products can lead to overproduction or over-purchasing, resulting in excess inventory.

- Market Changes: Shifts in consumer preferences, technological advancements, or changes in trends can render products obsolete. For example, technological products can quickly become outdated as new models are introduced.

- Seasonal Products: Items tied to specific seasons or holidays can become dead stock if not sold within their peak season. Unsold Christmas decorations, for example, may have little value once the holiday season passes.

- Quality Issues: Products with defects or quality problems that go unnoticed until after production can become unsellable, contributing to dead stock.

- Poor Inventory Management: Inefficient inventory management practices, such as lack of real-time tracking or improper categorization, can lead to the accumulation of unsold goods.

Impacts of Dead Stock

The presence of dead stock can have several adverse effects on a business:

- Tied-up Capital: Dead stock represents money that is invested in unsellable products, reducing the capital available for other business operations or investments.

- Storage Costs: Maintaining inventory requires storage space, and dead stock occupies valuable space that could be used for more profitable items. Additionally, prolonged storage can lead to increased costs for warehousing and maintenance.

- Obsolescence Risk: Over time, products may deteriorate, become outdated, or lose their market value, further diminishing the chances of selling them.

- Cash Flow Issues: Excess inventory can strain a company’s cash flow, affecting its ability to meet operational expenses and invest in new opportunities.

Strategies for Managing Dead Stock

Effective management of dead stock involves several proactive and reactive strategies:

- Accurate Demand Forecasting: Utilizing advanced forecasting tools and techniques can help predict demand more accurately, reducing the risk of overproduction or over-purchasing.

- Regular Inventory Audits: Conducting regular inventory audits helps identify slow-moving and dead stock early, allowing for timely intervention.

- Discounts and Promotions: Offering discounts, bundling products, or running special promotions can help move unsold inventory. Even selling at a reduced price is often better than letting the stock remain unsold.

- Return to Supplier: In some cases, suppliers may accept returns of unsold goods, especially if the items are still in good condition and within a certain time frame.

- Donations or Recycling: Donating unsellable products to charities or recycling them can help free up storage space and may offer tax benefits.

- Inventory Management Software: Implementing robust inventory management software provides real-time data on stock levels, sales trends, and potential dead stock, enabling better decision-making.

Dead stock is an inevitable challenge in inventory management, but with proactive strategies and efficient practices, its impact can be minimized. By understanding the causes of dead stock and implementing measures to prevent and address it, businesses can improve their inventory turnover, optimize storage space, and enhance overall profitability. In the competitive landscape of retail and manufacturing, managing dead stock effectively is a crucial aspect of maintaining a healthy and dynamic supply chain.