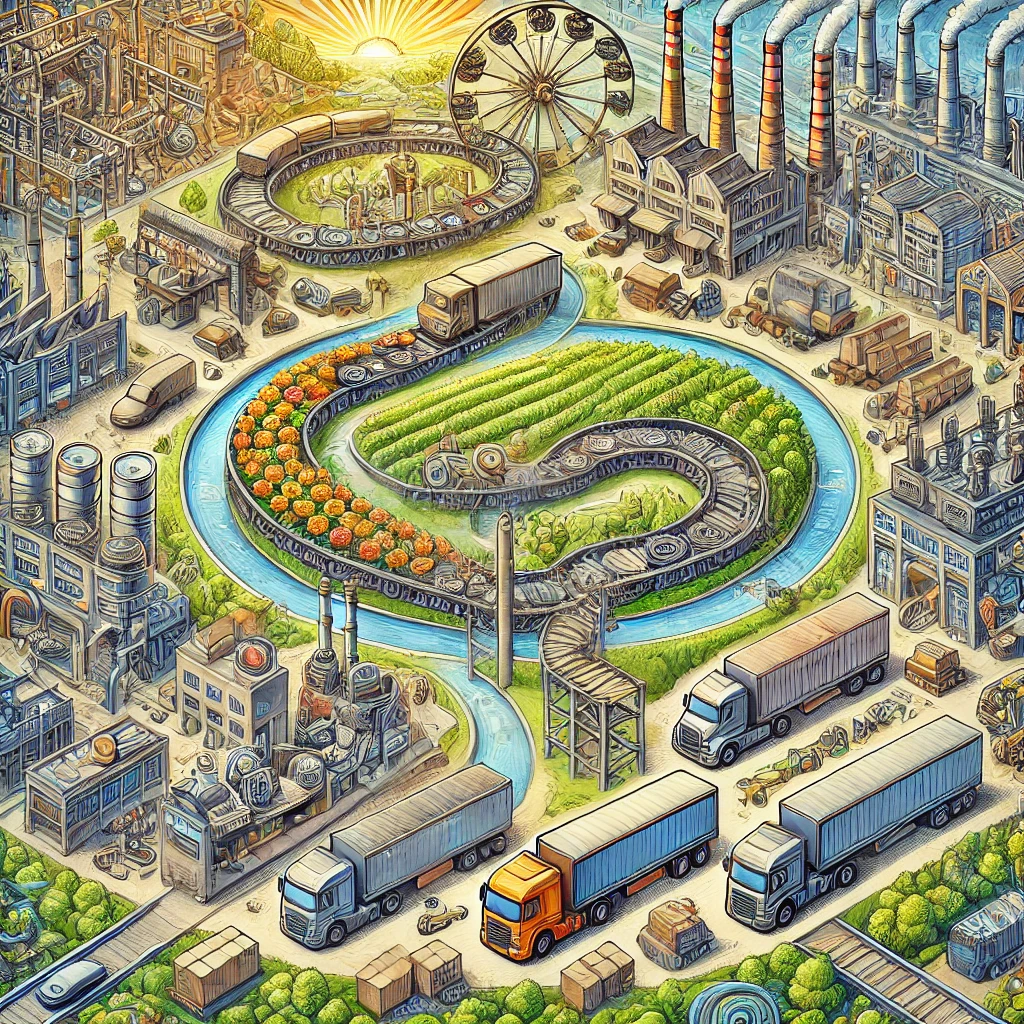

A supply chain encompasses the entire journey of a product, from the initial sourcing of raw materials to the final delivery of the finished product to the customer. This complex network of activities involves various entities including suppliers, manufacturers, and distributors. Effective supply chain management is crucial for businesses to ensure efficiency, cost-effectiveness, and customer satisfaction. This article explores the various components of the supply chain, challenges faced, and strategies for optimization.

Components of the Supply Chain

- Sourcing of Raw Materials: The supply chain begins with the procurement of raw materials. Suppliers must be carefully selected based on criteria such as price, quality, and reliability.

- Manufacturing and Production: Raw materials are transformed into products through manufacturing processes. This stage may involve multiple manufacturing sites and require sophisticated production planning and control.

- Distribution: Once products are manufactured, they need to be transported to distribution centers and stores. This involves logistics planning, warehousing, and inventory management.

- Delivery to Customers: The final stage of the supply chain is delivering the product to the customer, which can involve shipping to individual homes, retail locations, or other end points.

- Customer Service and Returns: Post-delivery services such as customer support, returns, and exchanges are also considered part of the supply chain and crucial for maintaining customer satisfaction and loyalty.

Challenges in Supply Chain Management

- Complexity: Managing a supply chain involves coordinating many interconnected activities, often globally. This complexity can lead to difficulties in synchronization and increased vulnerability to disruptions.

- Demand Forecasting: Accurately predicting customer demand is crucial but challenging. Misjudgments can lead to overproduction or stockouts.

- Cost Control: Balancing cost-efficiency with quality and speed is a constant challenge in supply chain management.

- Regulatory Compliance: Supply chains often span multiple countries, each with its own regulatory environment, adding to the complexity of operations.

- Sustainability Concerns: Consumers and governments are increasingly demanding sustainable practices, forcing companies to reconsider their supply chain strategies.

Strategies for Supply Chain Optimization

- Technology Integration: Implementing advanced technologies like IoT, AI, and blockchain can enhance visibility across the supply chain, improve efficiency, and reduce errors.

- Agile Practices: Adopting flexible and adaptive supply chain practices helps companies respond swiftly to market changes and disruptions.

- Supplier Relationships: Building strong relationships with suppliers ensures reliability and quality in the sourcing of materials.

- Lean Management: Employing lean management techniques can minimize waste and maximize efficiency within the supply chain.

- Risk Management: Developing robust risk management strategies is essential for mitigating the impacts of potential disruptions.

The Future of Supply Chain Management

The future of supply chain management is likely to be shaped by digital transformation, increased focus on sustainability, and the need for greater resilience against disruptions. Technologies like AI and blockchain will play significant roles in automating processes and securing data, while practices such as circular supply chains will become more prevalent to meet sustainability goals.

The supply chain is a critical component of business operations that requires strategic planning and management to ensure it functions smoothly and efficiently. By understanding and optimizing each component of the supply chain, businesses can enhance their operational efficiency, reduce costs, and improve customer satisfaction. As global dynamics and consumer expectations evolve, so too must supply chain strategies, adapting to new challenges and opportunities for innovation and growth.